Providing that all-important weatherproofing finishing touch to your residential or commercial roofing projects, flashings mark a critical and often time-sensitive stage of any construction. As your local roof manufacturing experts, we understand how important it is to have your custom roof flashings order go exactly to plan and just like you, we want you to avoid any lengthy or costly project delays. To help you with that, we’re sharing our top 5 tips for getting your flashings order right the first time!

Providing that all-important weatherproofing finishing touch to your residential or commercial roofing projects, flashings mark a critical and often time-sensitive stage of any construction. As your local roof manufacturing experts, we understand how important it is to have your custom roof flashings order go exactly to plan and just like you, we want you to avoid any lengthy or costly project delays. To help you with that, we’re sharing our top 5 tips for getting your flashings order right the first time!

Given the made-to-order nature of Pantex Roofing Systems flashings, and the incredible range of custom shapes and profiles available, it’s critical that we receive accurate information. That way, we’re able to manufacture exactly what you need! You may find our flashing order form assists you in providing all the necessary information. However, if you’ve ever wondered about how you can help ensure your custom roof flashings are right the first time, we’ve shared our tips for the top 5 things you need to check before placing an order:

Clearly mark the visible side

Our flashings can be ordered to match your other rainwater goods (choose from Zincalume® or the full range of 22 Colorbond® Steel colours). However, as flashings can be produced in many different shapes and designs, it will not always be obvious which side of your design should be coloured or visible. This side should be clearly marked. This applies to both Colorbond® and Zincalume® products to ensure either the coloured or non-branded side is visible.

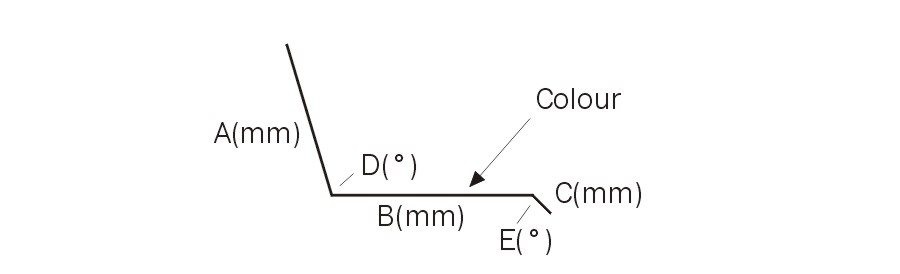

Specify the required dimensions

As flashings are custom made to suit your specific needs, no standard dimensions apply. It’s therefore important for you to include every dimension on your flashing drawing to ensure we meet your requirements the first time.

Be aware that the maximum flashing length is 8.0m

Our flashings are custom manufactured in both shape and length (to a maximum of 8.0m). So if you require a length beyond this, be sure to break it up into pieces less than 8.0m and allow for overlaps.

Ensure your angles are correct to suit the pitch of the roof

We know how easy it is to forget to include all your required flashings angles, or even getting the angles the wrong way around. A good rule of thumb is to double check whether an angle should be greater than or less than 90 degrees to help ensure you’ve noted the correct angle.

Select the most suitable material thickness

We have two thicknesses available to suit the needs of your specific project. It’s important that the thickness is specified on your order, as we can’t assume which thickness is right for you. Our 0.40mm BMT flashings are available in all girths (width) up to 400mm, and our 0.55mm BMT flashings are available in all girths (width) up to 1200mm.

We know you’ve got a lot on your plate when it comes time to placing your custom roof flashings order, but hopefully our tips will help you get your next order perfect the first time. Talk to us today about your flashings requirements. After all, we want to make your life easier!